The InPipe HydroXS® Energy Recovery System.

The InPipe HydroXS energy recovery system replicates the functionality of a control valve, creating precise pressure management and flow control. Instead of burning off the differential pressure, it creates renewable energy. This efficiency reduces operating costs, saves water, reduces carbon emissions, and extends the life of your infrastructure. The smart-control technology allows for real-time data collection for vastly improved verification.

Here’s how it works:

By monetizing this wasted pressure into electricity, you are making water more available, reliable, and affordable for your company and your customers. From a single HyrdoXS unit to a multi-unit, system-wide approach, the more you install the greater the impact on reducing energy costs, saving water and meeting your sustainability goals.

Benefits of turning water into Power.

Produces efficient, renewable energy.

Easily installs as a bypass onto existing pipeline.

Reduces carbon footprint.

Standardized, turnkey product.

Extends the life of infrastructure.

Creates an additional revenue stream.

Features and Specifications.

Unlike alternative custom-designed micro-hydro solutions, HydroXS is an end-to-end, standardized, turnkey product with advanced data management tools.

Real-time actionable data.

InPipe’s Flow and Pressure Management and Energy Recovery Dashboard provides real time 24/7 hydraulic information so you can track the impact of your NRW and Sustainability initiatives.

HydroXS Applications.

The HydroXS can be used in any potable water or wastewater installation where there is consistent flow and differential pressure, such as:

- Potable water distribution systems

- Wastewater facilities

- Industrial factories

- Water reuse facilities

Typical Installations.

- Control valve facilities where pressure reduction supplies a District Metering Area

- Supplying a reservoir, tank, well, or aquifer

- Pump stations supplying water distribution

- Raw water intake to a treatment plant

- Water reuse or desalination plants (RO)

- Water effluent flow from a wastewater treatment plant

Features and Specifications.

- Available in 7 sizes in pipe, sizes 2-inch to 110-inch (51 mm – 2.4 meters)

- NSF/ANSI 61 Approved for drinking water safety

- Pre-assembled and tested

- Real time data with Interactive dashboard

- SCADA-compatible

- 480V, 3-phase output

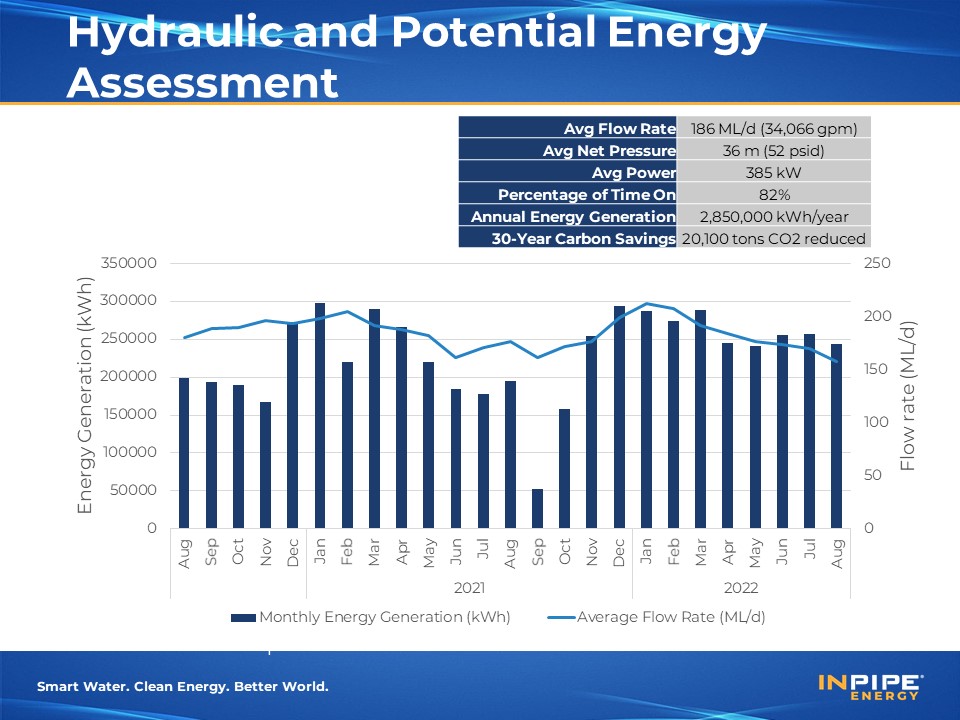

FREE Hydraulic & Potential Energy Assessment.

Take advantage of our free assessment that starts with identifying the amount of easily-accessible energy recoverable in your system and concludes with a report that includes detailed information, such as:

- Hydraulic analysis

- Accessible energy assessment

- Carbon emission analysis

- Summary of potential revenue

We know you’re busy, so we do the heavy lifting.

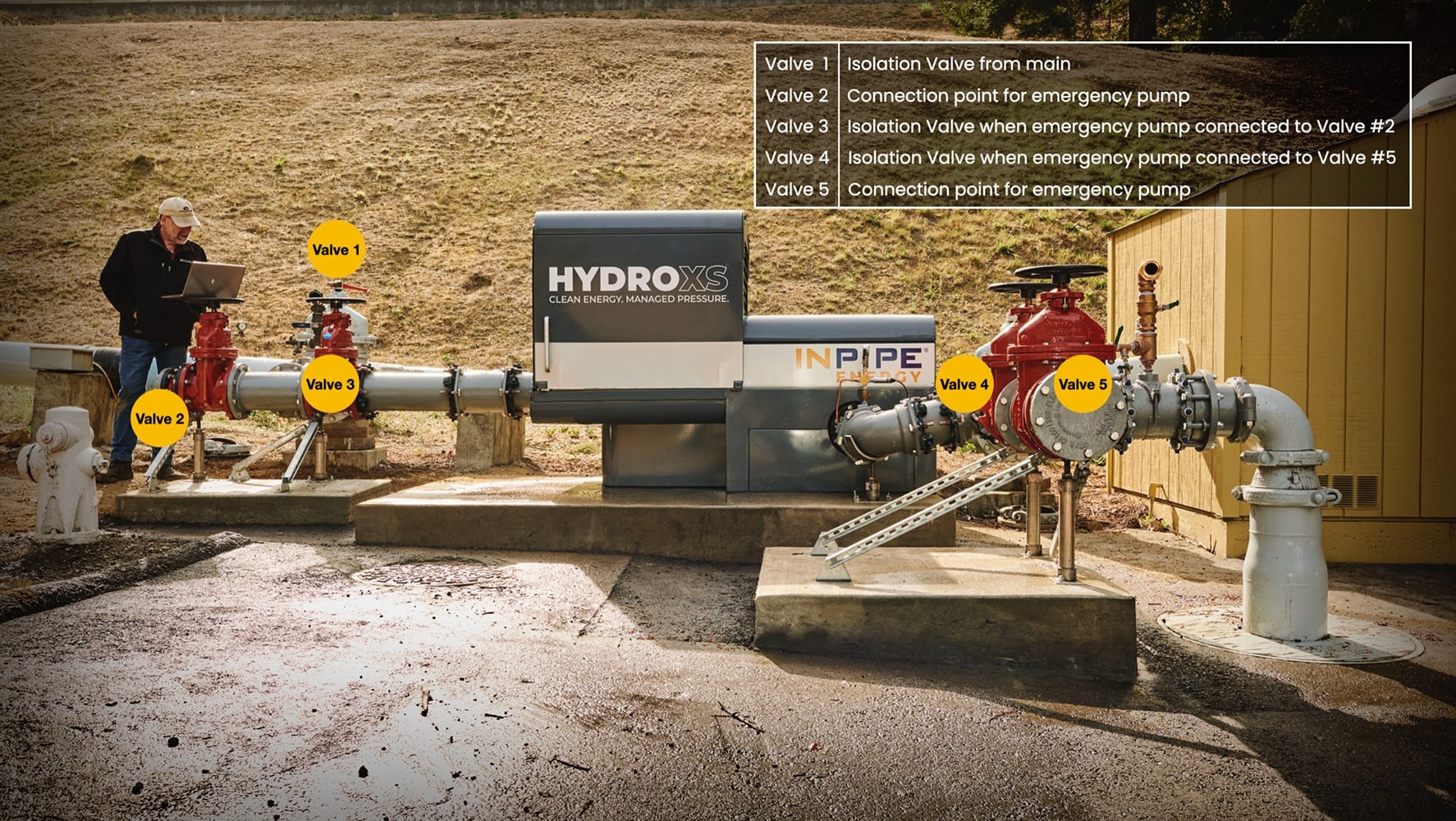

Installation Photo Questions.

We received these questions from engineers and operations managers on a recent InPipe Energy HyrdoXS installation photo. Please reference the value key and use your cursor roll-over question marks.

Q: Can you explain how the valves and microturbine are integrated and supported?

A: All the components in the HydroXS are combined flange to flange and supported by pipe supports within the enclosure for easy access and maintenance.

Q: What is this connection for?

A: This is for connecting a temporary pump. It included at the request of the customer.

Contact Us!

For information including funding options, please complete the below and submit.

An InPipe Energy specialist will contact you.

Take advantage of new government funding.

In 2022, the US Federal Government enacted the historic Inflation Reduction Act (IRA) that covers up to 50% of project costs for installing HydroXS energy recovery systems for water utilities, cities and municipalities. InPipe Energy can help you get started.